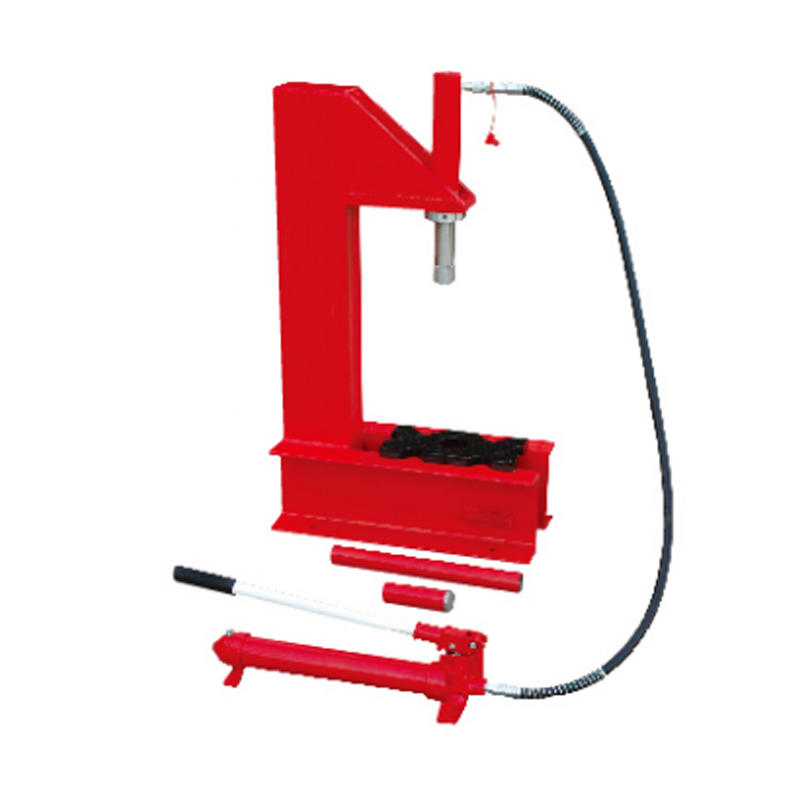

Powerful Precision: The Role of Shop Presses in Metal Fabrication

Shop presses are indispensable tools in metal fabrication shops, offering versatility and power for bending, straightening, and forming metal components. These robust machines provide a range of capabilities crucial to the fabrication process, allowing craftsmen to manipulate metal with precision and efficiency.

Bending Metal:

One of the primary functions of shop presses in metal fabrication is bending metal components to desired angles and shapes. Whether it's mild steel, aluminum, or other alloys, shop presses equipped with appropriate tooling enable craftsmen to bend metal with accuracy and consistency. By adjusting the pressure and positioning of the workpiece, operators can achieve precise bends essential for various fabrication projects, including forming brackets, frames, and structural elements.

Straightening Metal:

In metal fabrication, ensuring that metal components are perfectly straight is often paramount. Shop presses excel in straightening metal pieces that have been warped, bent, or distorted during manufacturing processes or due to external factors like impact or stress. Using specialized tooling and applying controlled pressure, craftsmen can gradually coax metal back into its original form, restoring structural integrity and dimensional accuracy.

Forming Metal:

Shop presses are invaluable for forming metal components into specific shapes and configurations required for diverse applications. Whether it's creating curves, contours, or intricate designs, shop presses equipped with various dies, molds, and tooling enable craftsmen to shape metal with precision and finesse. From automotive panels and decorative elements to industrial parts and machinery components, shop presses facilitate the transformation of raw metal stock into functional and aesthetically pleasing products.

Versatility and Customization:

One of the key advantages of shop presses in metal fabrication is their versatility and ability to accommodate a wide range of projects and materials. With adjustable pressure settings, interchangeable tooling, and customizable configurations, shop presses can adapt to diverse fabrication requirements and accommodate different metal thicknesses, shapes, and sizes. This flexibility allows craftsmen to tackle various fabrication challenges and explore creative possibilities in metalworking.

Precision and Control:

Precision and control are paramount in metal fabrication, and shop presses deliver on both fronts. With hydraulic systems capable of exerting immense pressure and fine-tuned controls, operators can manipulate metal with remarkable accuracy and responsiveness. Whether it's applying subtle adjustments or exerting significant force, craftsmen have the precision and control necessary to achieve desired results and meet exacting standards in metal fabrication.

Safety Considerations:

While shop presses offer unparalleled capabilities in metal fabrication, it's essential to prioritize safety when operating these powerful machines. Operators should receive thorough training on safe operating procedures, including proper handling of materials, equipment setup, and emergency protocols. Personal protective equipment (PPE) should be worn at all times to safeguard against potential hazards, such as flying debris, crushing injuries, and hydraulic system failures. Regular maintenance and inspections are also critical to ensuring the continued safety and reliability of shop presses in metal fabrication environments.

In conclusion, shop presses play a pivotal role in metal fabrication shops, empowering craftsmen to bend, straighten, and form metal components with precision, versatility, and control. From shaping structural elements to crafting intricate designs, shop presses enable craftsmen to transform raw metal stock into finished products that meet the highest standards of quality and craftsmanship in the fabrication industry. With a focus on safety, innovation, and craftsmanship, shop presses continue to be indispensable assets in the dynamic world of metal fabrication.

English

English Español

Español Deutsch

Deutsch