How durable and long-lasting are Creeper and steel seats in automotive workshop environments?

Creeper and steel seats are commonly used tools in automotive workshops due to their durability and long-lasting nature. As automotive technicians spend long hours working under vehicles and need to move around easily, these tools provide them with convenience, comfort, and safety. However, questions may arise about their durability and longevity in the demanding workshop environment.

Firstly, let's discuss the durability of Creeper seats. These are low-profile platforms mounted on wheels, allowing technicians to glide smoothly beneath vehicles. Creeper seats are usually constructed using sturdy materials such as heavy-duty steel frames or high-quality plastic. The wheels are typically made of durable rubber or polyurethane, ensuring smooth and effortless movement on workshop floors. These materials are chosen for their ability to withstand heavy weights, impact, and the wear and tear associated with daily workshop use.

Steel seats, on the other hand, are designed to provide comfortable seating options for technicians during their work. These seats often consist of a sturdy steel frame, padded cushions, and durable upholstery. The steel frame provides stability and is resistant to bending or warping even with constant use. The cushions are made using high-density foam that can withstand compression and retain its shape, providing long-lasting comfort for the user. The upholstery is usually made from tear-resistant materials, ensuring that it can withstand the rigors of a workshop environment.

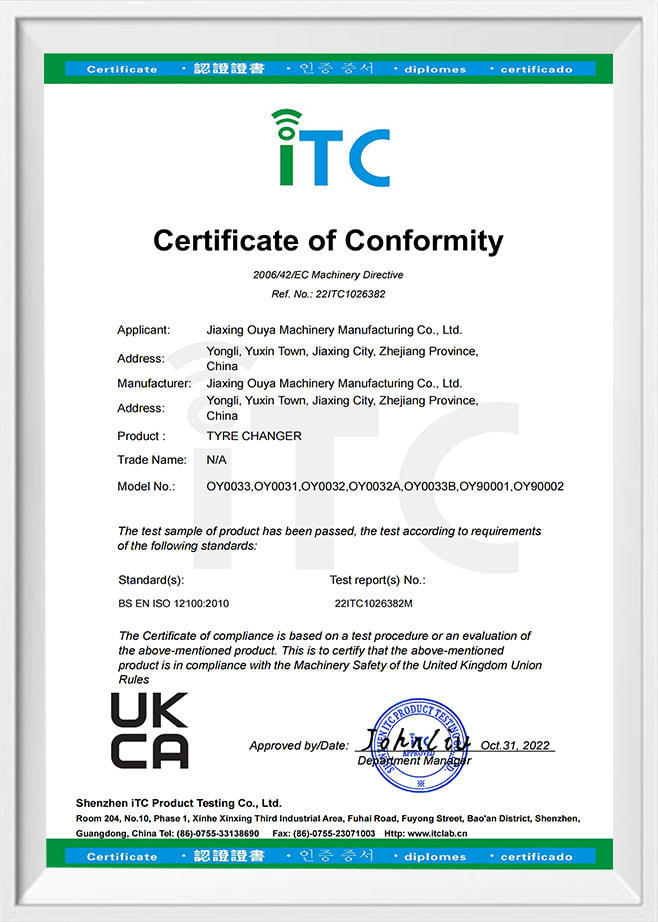

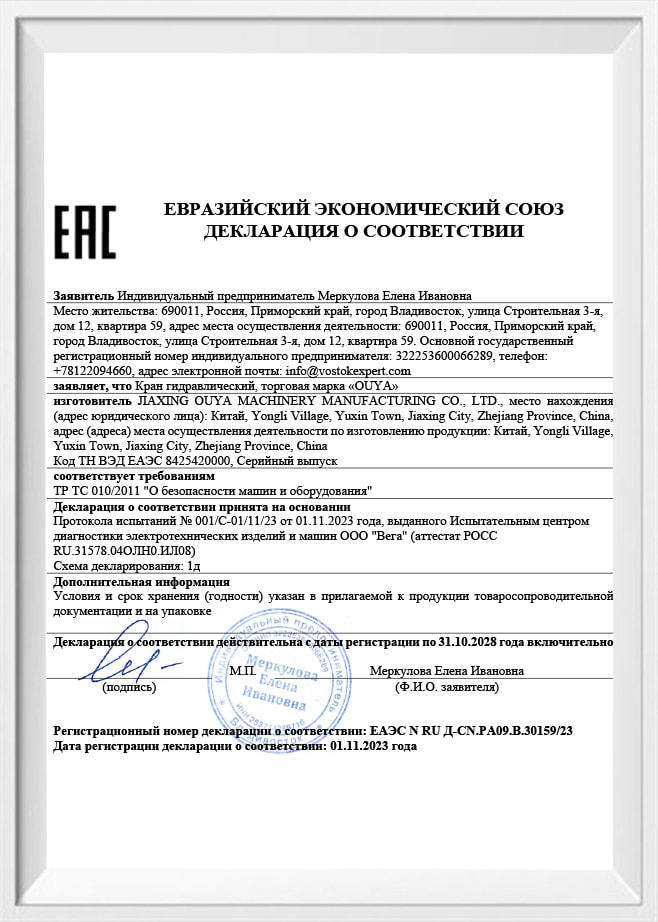

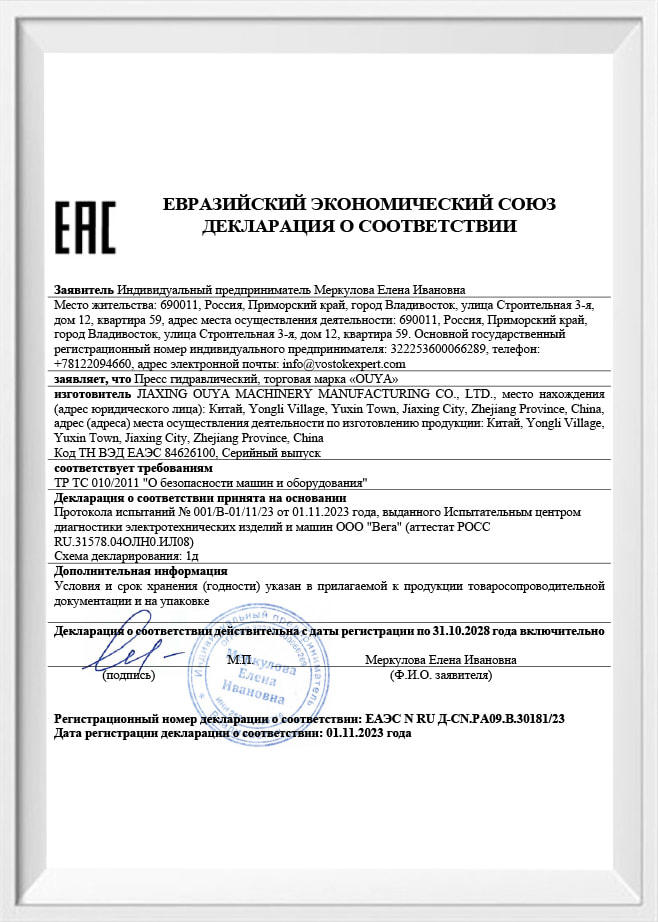

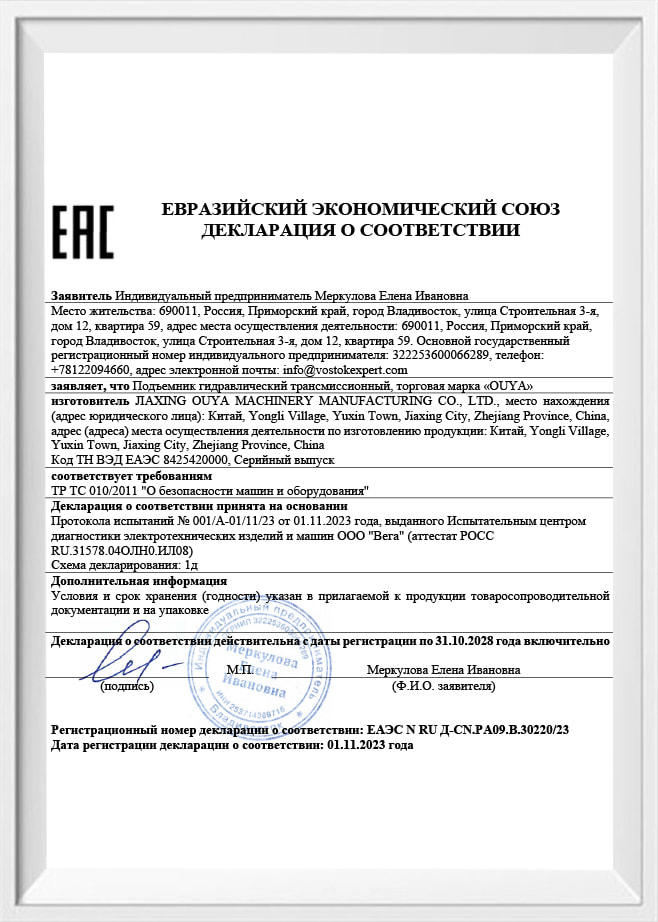

Both creeper and steel seats undergo rigorous testing and adhere to various safety standards to ensure their durability and long-lasting nature. Manufacturers take into account the demands of the automotive workshop environment and design these tools to withstand heavy loads, impacts, and harsh conditions such as oil, grease, and chemical exposure.

Proper maintenance and regular cleaning also contribute to the longevity of these tools. Regular cleaning removes debris, dirt, and chemicals that can accelerate wear and tear. Lubricating the wheels of a creeper and periodically checking and tightening the screws or bolts of a steel seat can help maintain their functionality and increase their lifespan.

It is important to note that the durability and longevity of Creeper and steel seats can also depend on the specific brand, quality of construction, and level of care they receive. Investing in reputable brands known for producing high-quality automotive tools can ensure better durability and longevity.

How do Creeper and steel seat designs contribute to overall technician comfort and well-being in automotive workshops?

The designs of Creeper and steel seats play a crucial role in promoting overall technician comfort and well-being in automotive workshops. These tools are specifically designed to provide ergonomic support and alleviate the physical strain that technicians may experience during long hours of work.

Creeper seats, for instance, are designed with padded cushions that offer a comfortable seating surface. These cushions are often made from high-quality foam materials that provide both softness and firmness to ensure optimum comfort. The padding to distribute the weight evenly, reducing pressure points and enhancing the sitting experience for technicians.

Furthermore, Creeper seats are with adjustable features such as backrests and headrests, allowing technicians to customize their seating position according to their individual preferences. This adjustability helps to maintain proper posture and alignment, reducing the risk of musculoskeletal disorders and providing relief to the spine,, and lower back.

In addition to the cushioning and adjustability, Creeper seats also feature built-in storage compartments, beverage holders and tool trays. These additional features ensure that technicians have easy access to their tools, parts, and refreshments, minimizing the need for them constantly move around and potentially strain themselves.

Similarly, steel seats are designed to provide stability and durability in automotive workshop environments. They are made from robust steel frames that can withstand constant use, heavy loads, and rough handling. The frames are often coated with corrosion-resistant materials, such as powder coating, to enhance their longevity even in challenging workshop conditions.

Moreover, steel seats have contoured shapes that follow the natural curves of the body to provide optimal support. Some models may include cushioning materials or padding that offer additional comfort during extended work periods. The seats are also typically designed at a height that allows technicians to work comfortably on vehicles without straining their backs or arms.

English

English Español

Español Deutsch

Deutsch